Start with a 50 pound block of 6AL-V4 titanium. Whittle away at it until your left with 0.060 wall thickness, that has to maintain a flatness of .002″.

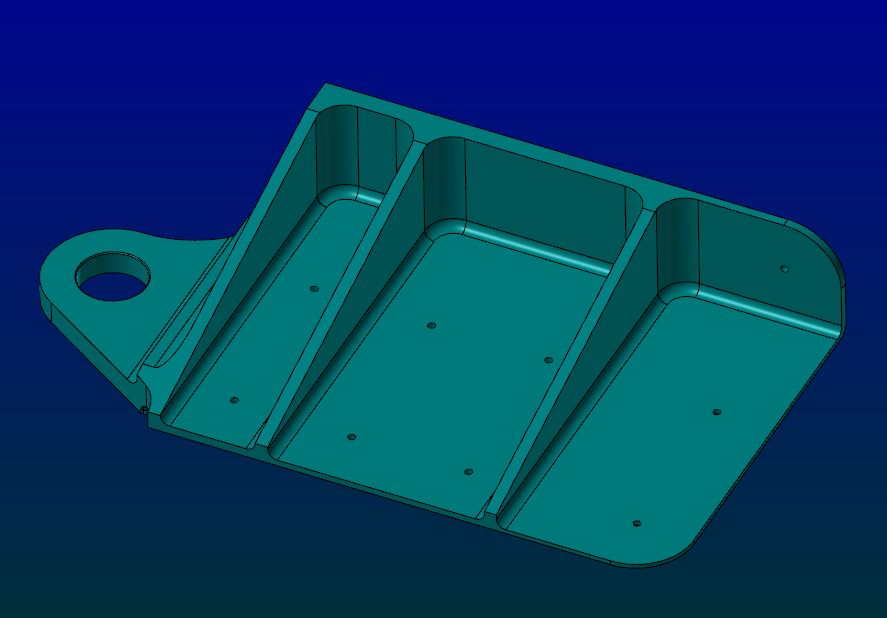

It looks so easy and straightforward, looking at the model in a CAM system. Just do some pocket roughing, some gentle finishing passes, some nice and slow finish facing, and your done.

It all comes out looking perfect when you render the model in the CAM system. Except the customer isn’t buying a model simulation. And titanium doesn’t cut in real life like it does in a simulator (or like any other metal, for that matter).

Titanium is a curious metal to cut. Titanium is tough, though it’s not hard, such as steels can become when heat treated. Titanium is also very flexible; you can bend in, but you can’t break it.

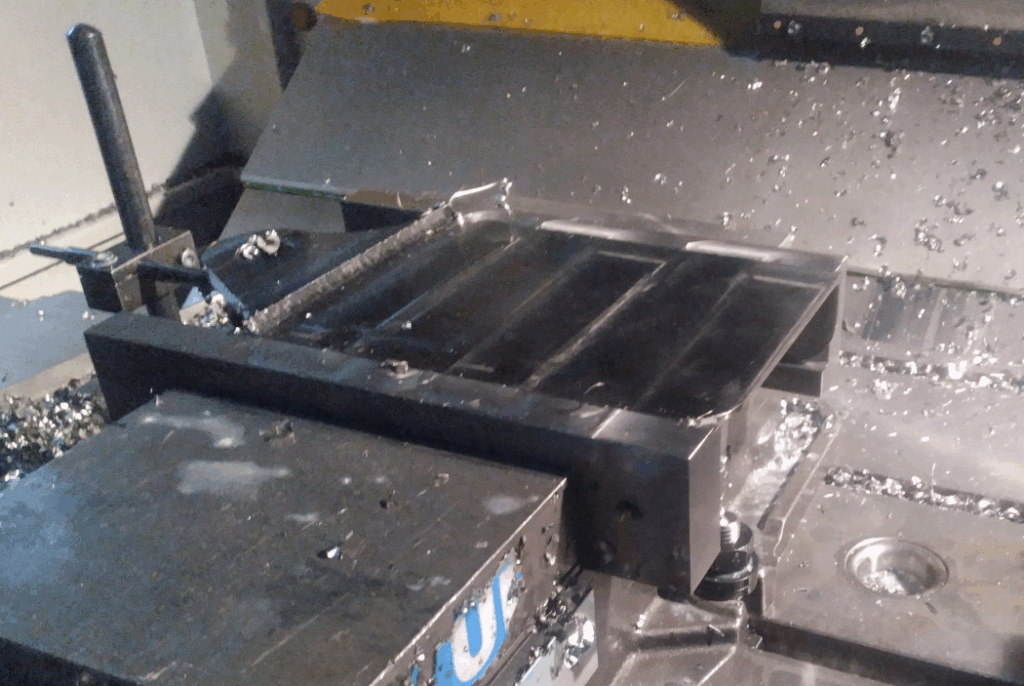

And it’s notorious for bending when you put a cutter to it. Especially if you’re targeting a .060″ thick wall. Without support underneath, the thin wall just deflects away from the cutter.

When trying to finish the bottom surface with a .060″ wall in a standard vise, the part moved down and away. Just finger pressure on the corner could deflect it .007″.

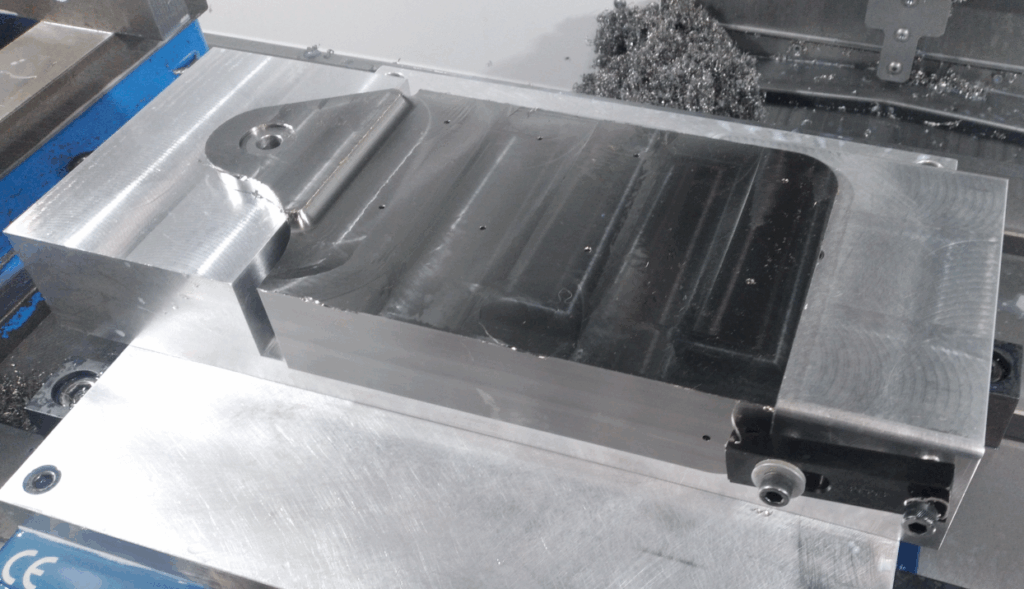

Our solution to keeping .002″ flatness across a continuous 30 square inch surface was to hold it down on a vacuum fixture. The fixture’s surfaces kept the part flush to the bottom, while the vacuum kept it from pulling up into the cutter. Any other potential movement such as sideways slippage was eliminated through the use of a simple clamp, a locater pin and careful consideration of cutting direction.

Although the fixture took considerable engineering and careful machining, using our VM300 vacuum system from @Miteebyte, a real problem turned into an easy finish pass.

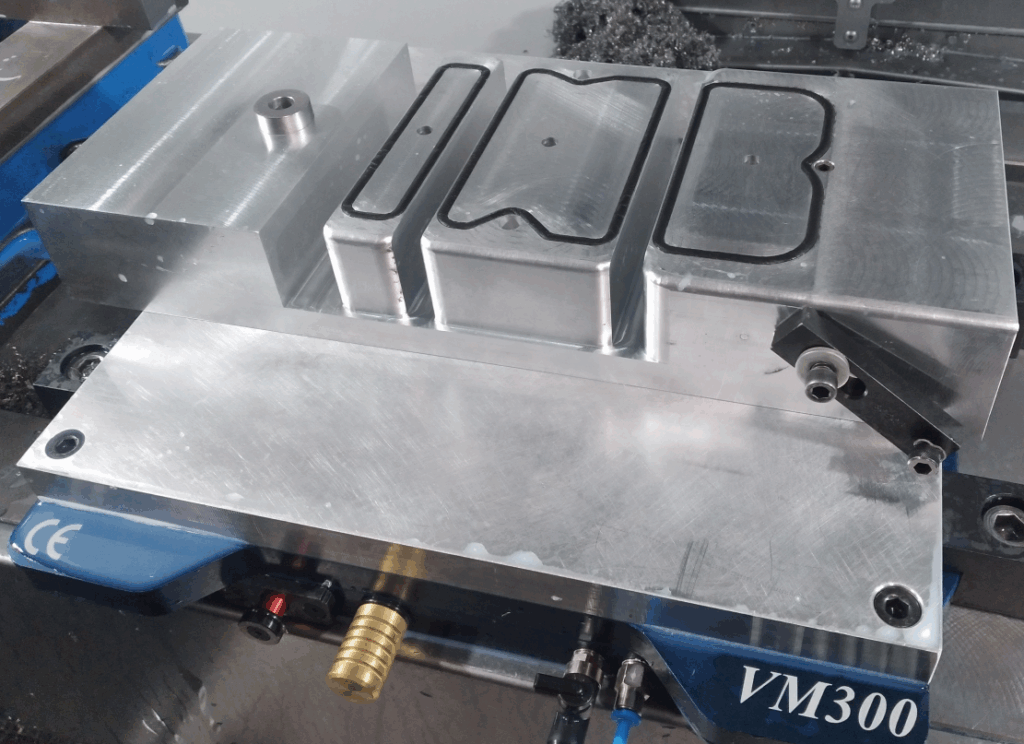

You can see the gaskets for maintaining the seals and the vacuum ports at the center of each. We figured that the surface area within the gasketed vacuum area equated to a total downward pressure of about 250 pounds, more than enough to hold everything in place for a 0.015″ facing cut with a 2.5″ face mill.

Nailed it. Problem solved!

Vacuum fixturing can be a real game changer. It isn’t the vacuum that holds the part down, it’s the atmospheric pressure on top pushing down (14.7 pounds per square inch at sea level, if you paying attention in school). The calculation is straightforward: calculate the area where the vacuum is applied and multiply by the factor above. (For us, being substantially above sea level, it’s closer to 14.0 lbs/ft2)